Asset-intensive companies require a clear understanding of the status of their assets to ensure the efficiency of their maintenance operations. If you are planning an EAM migration, this is the perfect time to make sure the information in your asset register is complete so that you can get the most out of your new EAM system. Without a complete asset register, your maintenance team may waste time locating information to complete work orders. As a result, outages and downtime may be extended, which would result in lost revenue for your company.

An asset register allows companies to obtain an accurate picture of the status, procurement date, location, make, model, and the serial number of their assets. However, the benefits of an asset register are stunted if it does not include accurate and complete information.

Assets Cannot be Tracked and Identified

It is hard to know if your asset register is complete by looking in your EAM or CMMS system as data may be unorganized, may not be grouped logically, or naming conventions may not make sense. It is important to identify missing assets or assets in the real world that have not been entered into your EAM or CMMS system. However, even when you think you have all the assets in your EAM or CMMS system, there could still be thousands of maintainable items that are missing.

A complete asset register allows you to identify and track your company’s assets, but information related to an asset register is often dynamic. To ensure and maintain the accuracy of your asset data, you need a solution that allows you to manage the information for your current assets effectively and manage the flow of information as these assets change and grow over time.

Maintenance and Repair Teams Cannot Rely on Asset Data

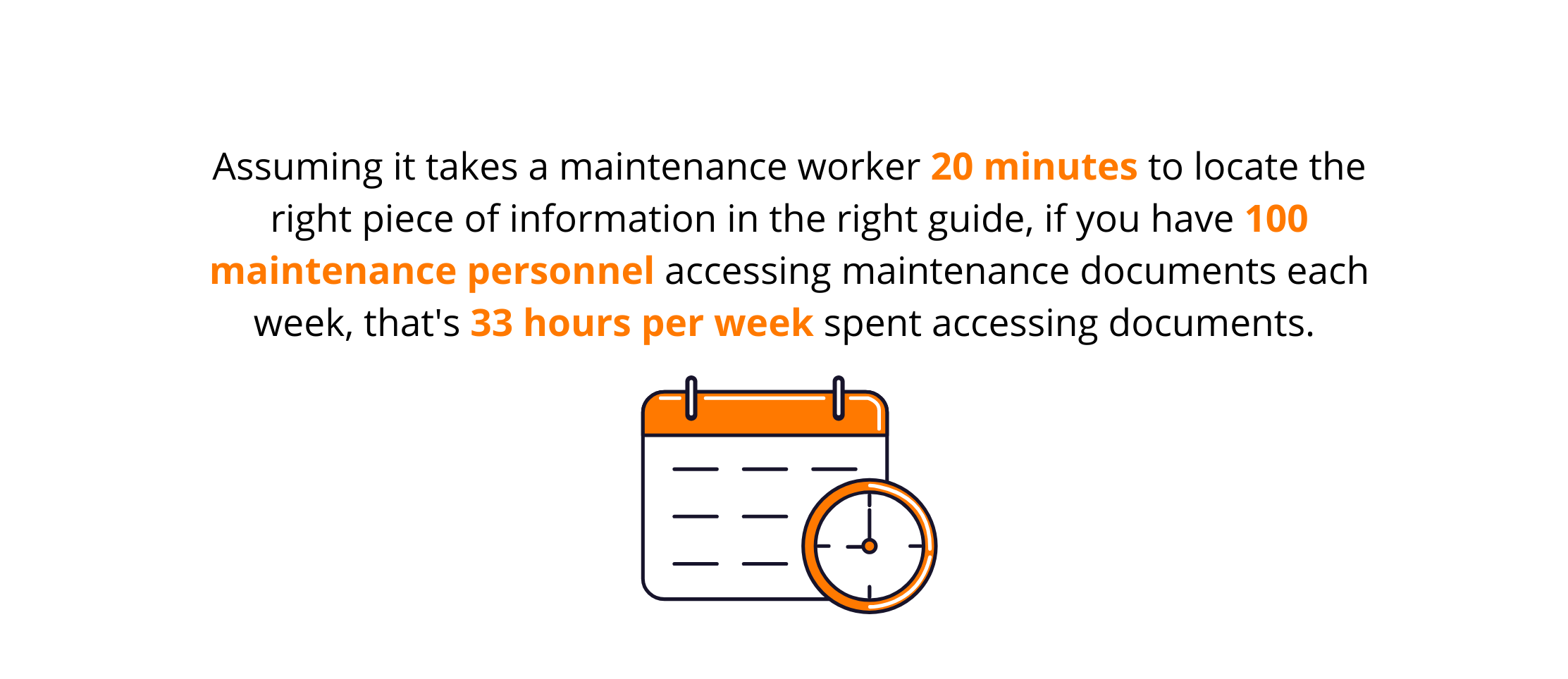

Quality asset data improves planning and allows for proactive maintenance planning. Without a complete asset register, you cannot estimate maintenance and repair costs. If your asset register does not contain complete and accurate asset data, then your maintenance technicians cannot rely on your asset data. They will have to engage in time-consuming tasks to obtain the necessary information to complete work orders. This may result in wasted time and money as well as critical errors.

By having the correct information at their fingertips, maintenance technicians can save time locating part numbers, reduce errors in identifying the right parts, and spend more time performing maintenance.

If you are planning an EAM migration, you should verify your asset register’s completeness before loading data into your new EAM system. Accurate asset data is required for proper maintenance operations, which are essential for ensuring the company’s safety, production, and revenue. NRX AssetHub, powered by HubHead Corp., provides maintenance and reliability professionals at asset-intensive businesses with world-class software solutions for analyzing, visualizing, building, editing, organizing, approving, and sustaining high-quality asset and maintenance data for their EAM and CMMS systems. If you would like to learn more about our solutions, do not hesitate to book a demo, and our team would be happy to help!

Your EAM is Only as Good as the Data you Feed it

Turn EAM / CMMS Data Nightmares into Dreams Come True!

Effective Asset Data Management Is Your Company’s Love Language

Share this article