Asset-intensive companies rely on the asset and maintenance master data in their EAM and CMMS systems to drive the maintenance and operations of their organizations. However, many companies fail to ensure that the master data in these systems is accurate and high-quality. Without an adequate data foundation, asset and maintenance management systems will fail to support the company.

The effect of bad master data extends across various aspects of maintenance and operations within an organization. It has significant impacts on the work management, knowledge management, and maintenance costs of a company.

Work Management

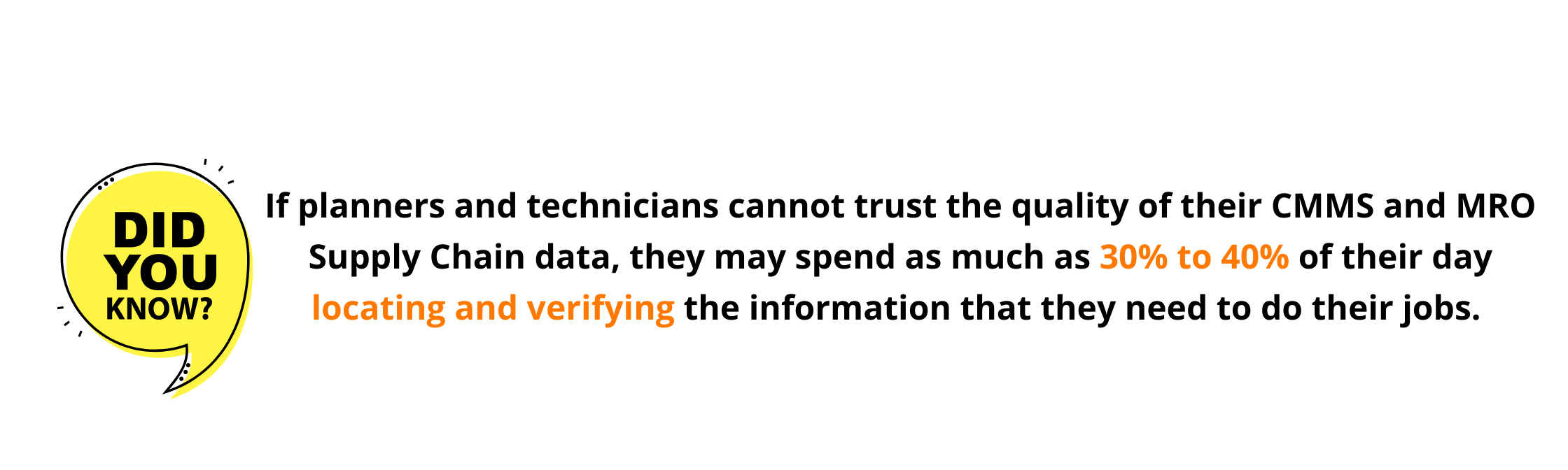

For work management to be effective and efficient, companies require a thorough understanding of the necessary processes, skills, and work and potential constraints they may encounter that would impact the ability for maintenance tasks to be completed. Companies cannot correctly define these aspects without accurate records of their assets and detailed, complete master data in their EAM or CMMS system. Inaccurate data in your system may lead to decreased wrench time, incomplete or incorrect work tasks and maintenance plans, as well as missing skills or inefficient use of specialized skills.

Knowledge Management

Detailed knowledge of maintenance information such as repair techniques, plant configurations, and spare part requirements is essential for maintenance workers. Over time, these workers gain an increasingly detailed and in-depth understanding of these components, and when they leave the company, this creates a knowledge gap. This gap needs to be filled with an IT system that can provide accurate maintenance information and effectively pass down this information from one generation of maintenance professionals to the next.

Maintenance Costs

Bad master data in an EAM or CMMS system can increase maintenance costs. Increased maintenance costs can arise because of obsolete part catalogues, missing critical spare parts, lack of preventative maintenance, or increased downtime. Reactive maintenance is two to five times more expensive than planned and predicted maintenance. To avoid escalating maintenance costs, you must ensure your EAM master data is accurate.

Bad master data will not be fixed by an EAM migration or upgrade. So, it is vital that you ensure the master data being migrated is accurate and detailed before completing a migration. To get the most out of your EAM or CMMS system, your master data must be high-quality and reliable. Better data powers maintenance productivity. It is essential that your master data is accurate before performing an EAM migration, or you will not experience all the benefits of your migration. NRX AssetHub, powered by HubHead Corp., provides asset-intensive businesses with world-class software for visualizing, building, editing, organizing, governing, and sustaining high-quality Asset and maintenance data for their EAM and CMMS systems. This allows companies to ensure their data is accurate before performing an EAM migration and avoids impacts to their work management, knowledge management, and maintenance costs. If you would like to learn more about our solution, book a demo, and our team would be happy to help you!

Your EAM is Only as Good as the Data you Feed it

Here’s What Happens to Maintenance When your EAM Data is Bad

Effects of Poor EAM Data on Operations

Share this article